Over time, equipment deterioration can lead to unexpected failures and costly repairs, making it important for you to adopt proactive strategies. One effective method is infrared scanning, a technology that allows you to detect potential issues before they escalate. By identifying hotspots and anomalies in your machinery, infrared scanning helps you maintain optimal performance and extend the lifespan of your assets. In this post, we’ll explore how you can implement infrared scanning in your preventative maintenance routine for improved efficiency and reliability.

Key Takeaways:

- Infrared scanning is an effective technology for identifying potential issues in electrical systems, mechanical components, and insulation before they lead to costly failures.

- Regular infrared inspections allow for trend analysis over time, helping to prioritize maintenance efforts and allocate resources more efficiently.

- Integrating infrared scanning into a preventative maintenance program enhances overall reliability and extends the lifespan of equipment, leading to reduced downtime and maintenance costs.

Overview of Infrared Scanning

For anyone looking to enhance their preventative maintenance strategy, understanding infrared scanning is imperative. This technology allows for the non-invasive inspection of equipment, identifying potential issues before they escalate into costly problems.

Definition of Infrared Scanning

Definition: Infrared scanning is a diagnostic technique that utilizes infrared thermography to detect heat patterns and variations within an object or system. By capturing the infrared radiation emitted from surfaces, you can assess temperature differences and identify anomalies indicating potential failures.

History and Evolution of Infrared Technology

Among the technological advancements of the last century, infrared scanning has seen remarkable growth. Initially developed for military applications, it has adapted for numerous commercial uses, including electrical inspections, building diagnostics, and predictive maintenance.

Infrared technology began in the early 1800s and continued to evolve, particularly during World War II, when it was used for night-vision capabilities. As the technology progressed, it found applications in thermography, where accurate temperature measurements of objects became possible. Today, infrared scanning is a common tool in various industries, aiding in the detection of overlooked faults and improvements in efficiency.

Types of Infrared Scanners

The following table outlines some common types of infrared scanners:

| Type of Scanner | Description |

| Handheld Scanners | Portable units used for quick inspections and spot-checking equipment. |

| Fixed-Mount Scanners | Stationary scanners monitoring specific areas continuously. |

| Thermal Imaging Cameras | High-resolution cameras providing detailed thermal images for in-depth analysis. |

| Surveying Drones | Drones equipped with infrared cameras for large-area inspections. |

| Predictive Maintenance Scanners | Advanced scanners utilizing analytics for proactive maintenance strategies. |

This variety ensures that you can find the right tool for your specific scanning needs. The advancement in each of these types has significantly improved efficiency and effectiveness in identifying and addressing issues early.

History: The progression of infrared scanners has resulted in several unique options, each tailored to specific applications. Understanding these various types can help you decide which is most suitable for your maintenance practices.

The following table summarizes more types of infrared scanners:

| Type | Use Case |

| Smartphone Attachments | Compact devices that convert your phone into a thermal imaging tool. |

| Portable Thermal Scanners | Lightweight tools ideal for technicians on the go. |

| Industrial Scanners | Robust units designed for heavy-duty inspection in manufacturing environments. |

| Remote Monitoring Systems | Advanced systems allowing for 24/7 thermal monitoring. |

| Specialized Scanners | Units designed for specific industries, such as electrical or mechanical applications. |

This knowledge will empower you to select the best infrared scanner for your unique requirements, facilitating more efficient maintenance processes.

Benefits of Infrared Scanning in Maintenance

While traditional maintenance methods can sometimes lead to unexpected downtime and costly repairs, infrared scanning presents a proactive approach to equipment care. If you’re interested in enhancing your maintenance strategies, consider Using Infrared Thermography to Improve Electrical …. This technology not only identifies hidden problems but also optimizes your resources for better overall performance.

Early Detection of Issues

Around your equipment, minor temperature fluctuations can indicate larger problems. Infrared scanning enables you to detect these anomalies early, allowing you to address issues before they escalate into serious breakdowns. This preventive action protects your assets and ensures the longevity of your systems.

Cost Savings and Efficiency

To maintain an effective operational budget, implementing infrared scanning can significantly reduce maintenance costs. By identifying issues before they result in full-blown failures, you save on unexpected repair expenses and avoid costly downtime.

Maintenance practices that incorporate infrared scanning allow you to schedule repairs at your convenience rather than reactively at an inconvenient time. This not only improves your operational efficiency but also enhances productivity across your business, ensuring your team can focus on core tasks instead of emergency fixes.

Non-Destructive Testing

Against the traditional maintenance approaches, infrared scanning offers a non-invasive solution that doesn’t interfere with your equipment’s operation. You can conduct assessments without shutting down systems, preserving workflow and minimizing interruptions.

NonDestructive testing through infrared scanning ensures that you gather valuable data about your equipment without risking damage. This method allows you to keep an ongoing record of thermal profiles, making it easier to track the health of your assets over time and make informed maintenance decisions.

Common Applications of Infrared Scanning

Once again, infrared scanning proves to be a valuable tool in a variety of settings. This technology enables you to identify potential issues before they escalate, ensuring the longevity and efficiency of your systems.

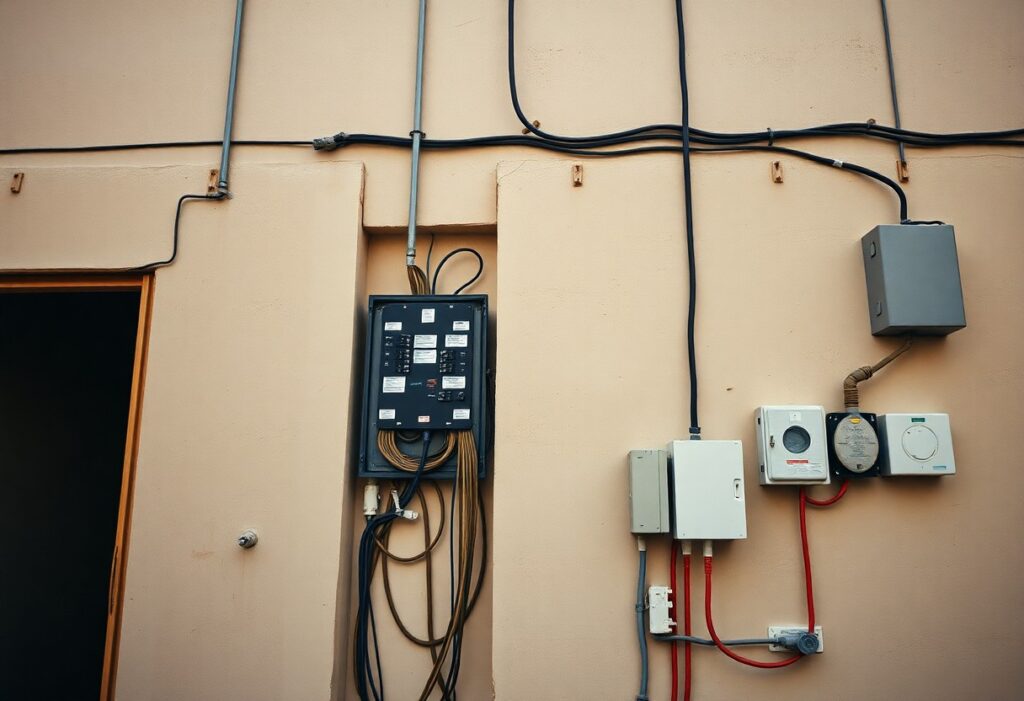

Electrical Systems

By utilizing infrared scanning, you can detect hotspots in electrical systems that may indicate overloads, loose connections, or failing components. This proactive approach helps you maintain system reliability and prevent unexpected failures.

Mechanical Equipment

Before checking your mechanical equipment with infrared scanning, ensure you understand how thermal imaging can reveal misalignments, wear and tear, or lubrication issues. By detecting these problems early, you can schedule repairs, reducing downtime and enhancing performance.

The importance of regular infrared monitoring for mechanical equipment cannot be overstated. You will gain insights into various moving parts and machinery, helping you assess their operational efficiency and optimize maintenance practices effectively.

Building and Structural Inspections

Inspections using infrared scanning allow you to pinpoint potential weaknesses in building envelopes and structures. This method enables you to find moisture intrusion, insulation defects, or air leaks that may compromise the integrity and efficiency of your property.

Even small issues detected through infrared scanning can lead to significant building problems if neglected. By addressing these findings promptly, you are safeguarding your property, enhancing energy efficiency, and ultimately saving on costly repairs down the line.

HVAC Systems

The inspection of HVAC systems through infrared scanning allows you to spot discrepancies in temperature and airflow that could indicate inefficiencies or system failures. You can optimize your HVAC operations and maintain comfort in your spaces.

It is important to conduct regular assessments of your HVAC systems to ensure they are functioning correctly. By using infrared scanning, you can identify leaks or blockages in ductwork and detect issues in compressors, ensuring your systems operate at peak efficiency and maintain a healthy environment.

Conducting an Infrared Inspection

Keep in mind that thorough preparation is key to a successful infrared inspection. Before you begin, ensure all thermal imaging equipment is in optimal condition. Calibrate your infrared camera according to the manufacturer’s guidelines, check the battery levels, and clean the lens to avoid any obstructions that could affect image quality. Having the right accessories, such as tripods and protective gear, will also enhance your inspection process.

Equipment Preparation

Any detailed inspection requires that you have the right tools at your disposal. Verify that your infrared camera is functioning correctly and that you’ve charged it fully. Ensure that you have sufficient storage for the captured images and any software you will need for data processing afterward. Additionally, take the time to familiarize yourself with the camera settings to optimize your results during the inspection.

Inspection Procedure

Across various environments, the inspection procedure generally follows a consistent approach. Begin by identifying the areas you intend to scan, focusing on hotspots like electrical components and mechanical equipment. Use your infrared camera to capture images, ensuring you take multiple angles for each target. It’s vital to maintain a consistent distance and angle when capturing images for accurate thermal readings.

Infrared scanning involves collecting thermal images while observing the equipment’s operational state. Perform inspections during peak operational times to capture accurate temperature differentials. Use appropriate starting points, such as electrical panels and motor bearings, and systematically cover each area methodically. This approach allows you to gather comprehensive data that can help you understand the thermal behavior of your equipment.

Data Analysis and Interpretation

Beside capturing images, analyzing and interpreting the data is fundamental to effective maintenance planning. After your inspection, review each thermal image for anomalies, such as hotspots or unexpected temperature patterns that may indicate potential issues. Compare these findings against historical data to establish any significant changes over time.

Indeed, the analysis phase is where you identify trends and compile actionable insights from your thermal images. By cross-referencing the thermal data with equipment specifications and maintenance histories, you can effectively prioritize which areas need immediate attention and which can be monitored over time. This data-driven approach ensures that your maintenance efforts are focused and efficient, helping to reduce downtime and enhance equipment longevity.

Best Practices for Effective Infrared Scanning

Many facilities are discovering the benefits of infrared scanning as a proactive measure for maintenance. To ensure you achieve the best results, it is important to follow best practices that enhance the effectiveness of your infrared scanning efforts. For insights on successful infrared scanning maintenance, check out this resource on Infrared Scanning Maintenance – Keys to Success.

Training and Certification

Against the backdrop of advancing technology, ensuring your team is adequately trained and certified in infrared thermography is imperative. By investing in comprehensive training, you enhance your capability to effectively identify and analyze thermal issues within your equipment.

Regular Inspection Scheduling

Any maintenance program benefits from a regular schedule for infrared inspections. Consistency helps you track changes over time and catch potential issues before they escalate into major problems.

To establish a successful inspection schedule, consider the operational demands of your facility and the criticality of your equipment. Setting regular intervals for infrared scanning allows you to monitor components effectively and ensures that you are not overlooking any areas that may warrant attention.

Documentation and Reporting

After completing an infrared scan, thorough documentation and reporting of your findings are vital. This practice not only facilitates tracking the health of your equipment but also aids in planning future maintenance interventions.

A well-organized report will detail findings, including images and temperature data, helping you to analyze trends and make informed decisions. By maintaining a clear record, you can also provide valuable information for safety audits, compliance, and continuous improvement efforts throughout your facility.

Case Studies and Examples

All businesses can benefit from infrared scanning as a preventive maintenance tool. Here are detailed case studies showcasing its effectiveness:

- Case Study 1: A manufacturing facility reduced unscheduled downtime by 30% over a year after integrating infrared scanning into their maintenance strategy, detecting 15 potentially hazardous electrical faults before they caused failures.

- Case Study 2: A commercial building identified and repaired 10 insulation defects through infrared scanning, resulting in a 20% decrease in energy consumption.

- Case Study 3: A chemical plant avoided potential fire hazards and saved an estimated $100,000 in damages by uncovering wear in heating systems using regular infrared inspections.

- Case Study 4: A government facility implemented infrared scanning to inspect HVAC systems, which led to a 15% improvement in energy efficiency and a payback period of just 6 months.

- Case Study 5: After using infrared technology for routine checks, a logistics company enhanced its operational reliability, experiencing a 40% drop in delayed shipments associated with equipment failure.

For more insights, check out this article on Why Infrared Scanning should be a part of every maintenance … plan.

Industrial Applications

Between various manufacturing sectors, infrared scanning serves as a proactive measure to identify risks in electrical systems, mechanical components, and structural integrity, ensuring optimal performance and safety.

Commercial Facilities

Applications of infrared scanning in commercial facilities lead to enhanced energy efficiency and reduced operational costs. By regularly inspecting heating and cooling systems, you can sustain comfortable environments while lowering utility expenses.

The impact of infrared scanning goes beyond simple energy management. It allows you to pinpoint thermal leaks and mechanical anomalies, ultimately extending the lifespan of your HVAC systems and increasing ROI on maintenance investments.

Government and Institutional Use

Against the backdrop of budget constraints, government facilities are embracing infrared scanning to monitor crucial equipment and save resources while ensuring public safety and service reliability.

Industrial applications for government and institutional use frequently highlight the necessity of compliance with regulations and standards. By integrating this technology, you not only protect assets but also create a transparent maintenance culture that can justify funding and meet operational goals effectively.

Final Words

Ultimately, incorporating infrared scanning into your preventative maintenance strategy can significantly enhance the reliability and efficiency of your operations. By identifying potential equipment failures before they escalate, you can save time, reduce costs, and maintain optimal performance. Embracing this technology not only protects your assets but also fosters a culture of proactive maintenance within your organization, ensuring that you stay ahead in a competitive landscape.

FAQ

Q: What are the benefits of using infrared scanning in preventative maintenance?

A: Infrared scanning allows for the detection of temperature discrepancies in electrical and mechanical systems, which can indicate potential failures. By identifying hot spots and temperature anomalies before they lead to breakdowns, companies can perform maintenance tasks proactively. This not only reduces downtime but also extends the lifespan of equipment. Additionally, it improves safety by minimizing the risk of accidents associated with overheated components.

Q: How often should infrared scanning be performed for the best results in maintenance?

A: The frequency of infrared scanning largely depends on the operation and criticality of the equipment. Generally, it is suggested to conduct scans quarterly or biannually for key electrical and mechanical systems. However, high-demand environments may require monthly inspections. Ultimately, establishing a tailored schedule based on equipment usage and operating conditions ensures optimal monitoring and maintenance.

Q: What training is necessary to effectively use infrared scanning technology in preventative maintenance?

A: To effectively utilize infrared scanning technology, personnel should undergo specific training that covers the operation of infrared cameras, analysis of thermal images, and interpretation of temperature data. Additionally, knowledge of the systems being inspected is important. Certification programs are available to provide in-depth training, helping operators to accurately identify issues and make informed maintenance decisions based on their findings.